Add Date: 2024/5/28 Views: 540

Keyword:Small five axis machining center,Small five axis linkage machining center,Desktop machining center, Teaching CNC machine tool,Five axis machining center

With the rapid development of manufacturing and continuous technological progress, the demand for high-end technical talents is increasing day by day. The five axis linkage technology, as an important means to solve the problem of efficient and high-quality machining of complex parts with opposite characteristics, has received widespread attention. Therefore, it is particularly important to cultivate professional talents who master the five axis linkage technology.

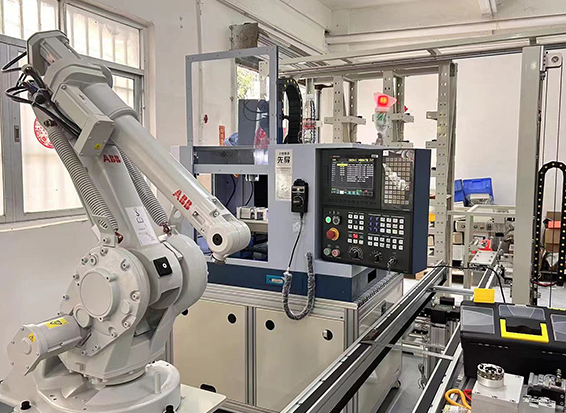

The pilot small five axis machining center provides a real operating environment, allowing students to learn and master the five axis linkage technology in practice, and improve teaching effectiveness.

Students can gain a deeper understanding of the principles and processes of five axis machining by directly operating a small five axis machining center, and deepen their understanding of theoretical knowledge.

1、 Characteristics of Small Five Axis Machining Centers

Small footprint: Compared to large five axis machine tools, small five axis machining centers have a smaller footprint and are suitable for use in educational institutions such as schools.

Fully functional: Although small in size, the small five axis machining center still has the function of five axis linkage, which can process complex parts.

Suitable for teaching: Small five axis machining centers are relatively inexpensive and easy to operate, making them suitable for school teaching and experimentation.

2、 Application in educational equipment

Practical teaching: The small five axis machining center provides a practical operation platform for CNC technology students, enabling them to master the five axis linkage technology in practice.

Skills training: By operating a small five axis machining center, students can enhance their CNC programming and operation skills, laying a solid foundation for their future career development.

Research experiments: Small five axis machining centers can also be used for research experiments, helping researchers explore new processing technologies and processes.

3、 The relationship with educational equipment

Supplement and Expansion: As a part of educational equipment, small five axis machining centers provide beneficial supplements and extensions for traditional mechanical processing teaching.

Improving teaching quality: By introducing advanced equipment such as small five axis machining centers, the teaching quality of CNC technology majors can be improved, and more high-quality talents that meet market demand can be cultivated.

Promoting professional development: The application of small five axis machining centers has promoted the development and innovation of CNC technology, providing strong support for scientific and technological progress in related fields.

Introducing advanced equipment such as leading digital small five axis machining centers can promote the development and innovation of CNC technology majors, improve teaching quality, cultivate high-quality talents, and promote professional development, providing students with more cutting-edge knowledge and skills.

Students can learn about the latest industry trends and technological trends through practical operations, and prepare for future career development.

In summary, the application advantages of the pilot small five axis machining center in educational equipment are mainly reflected in its strong teaching practicality, suitability for teaching places, easy operation, cost reduction and efficiency improvement, strong adaptability and wide application, as well as promoting professional development and innovation. These advantages make small five axis machining centers one of the important equipment for teaching and experimentation in the field of numerical control technology in schools.