CNC machine tool is a kind of machine tool that uses digital information to control mechanical movement and machining process, which is widely used in various fields, such as aviation, automobile, mould, military industry and so on.

CNC machine tool is a kind of machine tool that uses digital information to control mechanical movement and machining process, which is widely used in various fields, such as aviation, automobile, mould, military industry and so on.

Desktop CNC machine tools are small but complete; mini CNC lathe, safe to use, with the standard structure of large industrial CNC machine tools and CNC programming, operation, processing functions

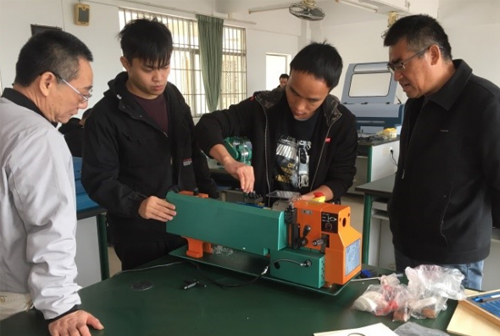

Vocational numerical control teaching practice in addition to the study of cultural courses, especially pay attention to practical ability, is employment-oriented. Therefore, in the teaching arrangement, students' operation experiment classes account for more.

金属加工车床是一种工具,它产生圆柱形对称材料。 最初车床只用于金属,但今天他们也用于切割木材,塑料和其他材料。

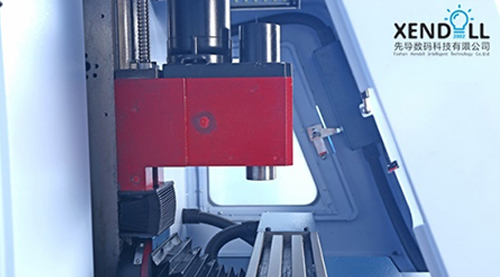

Micro machine tools, labor technology room equipment, numerical control teaching training, maker tools and machine tools, campus innovation room, comprehensive practice room, high strength industrial steel plate, to ensure the overall operating life of the equipment.

1, the knife, the tool strength is not enough too long or too small, resulting in the tool knife. 2. Improper operation by the operator. 3. Uneven cutting allowance. 4. Improper cutting parameters.

|Along with the speeding up of our industrialization process, the domestic numerical control machine tool demand for functional parts is more and more urgent. How to speed up the production of domestic CNC machine tool functional parts, equipment manufacturing industry as a pillar industry, requires faster development.

According to the manufacturer of pilot CNC lathes, the main reasons for fixture errors in the operation of CNC lathes are the low manufacturing precision and installation precision of each fixture component,

Model: C33, equipped with 2.2KW spindle motor (can be rigid tapping),X, Y, Z axis using high precision grinding ball screw, using Taiwan silver rail, high precision, equipped with a wide 980MDc numerical control system