Add Date: 2024/11/21 Views: 1

The working principle of the five-axis CNC machine tool is to achieve complex three-dimensional positioning of the tool relative to the workpiece and cutting path control through the precise coordination of three linear axes (X, Y, Z) and two rotational axes (A, C). This multi-axis linkage technology enables the machine tool to complete high-precision processing of multiple surfaces and even complex curved surfaces of a part in a single clamping operation.

Due to its high precision and capability for processing complex curved surfaces, the five-axis CNC machine tool is widely used in fields such as aerospace, automobile manufacturing, precision mold making, shipbuilding, and medical equipment. These fields have extremely high requirements for the shape and precision of components, which the five-axis CNC machine tool can fully meet.

The use of five-axis CNC machine tools is becoming increasingly widespread. However, due to the high cost of industrial-grade models, they are not suitable for teaching operations. On the other hand, educational, small-scale five-axis CNC machine tools are smaller in size, occupy less space, and have a more economical cost that is more suitable for schools.

By learning to operate five-axis CNC machine tools, students can stay connected with social enterprises and acquire advanced numerical control knowledge in advance.

The five-axis CNC machine tool can complete high-precision processing of multiple surfaces and even complex curved surfaces of complex parts in a single clamping operation, reducing errors caused by multiple clamping and thus improving overall processing precision.

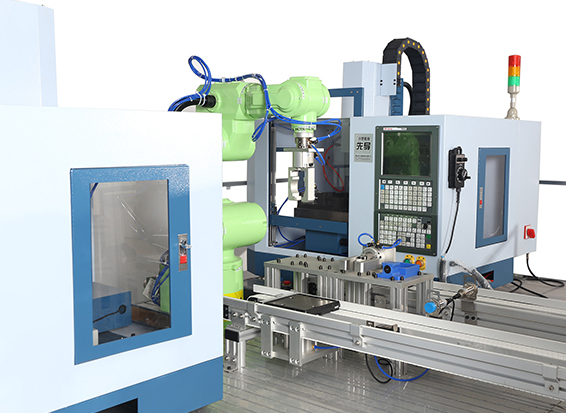

Desktop Five-Axis Simultaneous CNC Machine Tool, Model C220-5

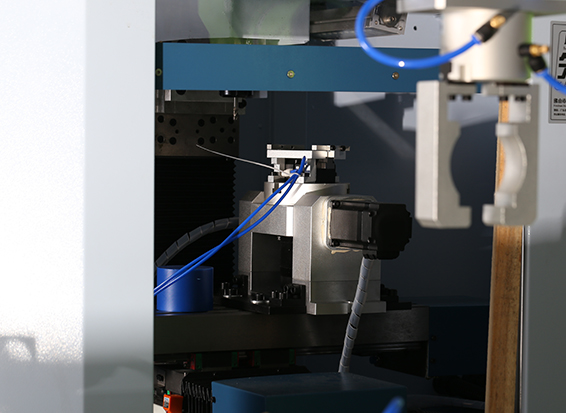

Features a fully enclosed structure with transparent plexiglass, employs high-precision linear guides, is cast from high-quality cast iron material, and utilizes high-precision ground ball screws. This machine is equipped with a standard industrial-grade CNC system capable of five-axis simultaneous operation. It comes with a high-precision spindle motor, featuring a spindle power of 1.1Kw and a spindle speed of 6,000 RPM. The X, Y, and Z axes utilize precise linear guides and are equipped with a centralized multi-channel lubrication system.

Technical Parameters:

|

Positioning Accuracy |

0.02mm |

|

Repetitive Positioning Accuracy |

0.01mm |

|

Travel of X/Y/Z Axes |

220/120/200mm |

|

Travel of B Axis |

+30~-120° |

|

Travel of C Axis |

360° |

|

Spindle Chuck Taper |

ER25 |

|

Spindle Power |

1.1kW |

|

Spindle Speed |

6000rpm |

|

Maximum Tool Clamping Diameter |

16mm |

|

Table Size |

400*140mm |

|

Table Load Capacity |

15kg |

|

T-Slot |

12mm/3 |

|

X/Y Axes Moving Speed |

6000mm/min |

|

Z Axis Moving Speed |

4000mm/min |

|

B/C Rotary Axes Moving Speed |

20r/min |

|

Axes Simultaneity |

Five axis five linkage, adopting a cradle style structure |

|

Automatic Door |

Up and down automatic switch |

|

Operating Voltage |

AC220V/50H |

The high precision and stability of the five-axis CNC machine tool ensure that the processed products are of more reliable quality. It reduces the scrap rate due to processing errors, improves product conformity rates, and enhances customer satisfaction.

Driving Technological Innovation and Industrial Upgrades: The application of five-axis CNC machine tools promotes technological innovation and industrial upgrades in the manufacturing industry; it fosters the development of intelligent manufacturing and automated production, enhancing the overall competitiveness of the manufacturing sector.

EN:

Keywords:#Desktop Five-Axis CNC Machine Tool, # Small Five-Axis CNC Milling Machine, # Educational Five-Axis Simultaneous CNC Milling Machine, # CNC Practical Training Machine Tool, # Desktop-Class Five-Axis CNC Machine Tool

WEBSITE:www.xendolltools.com

Youtube:xendoll